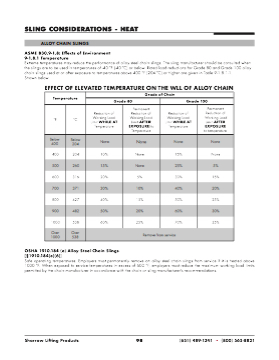

SLING CONSIDERATIONS - HEAT ALLOY CHAIN SLINGS ASME B30.9-1.8: E ects of Environment 9-1.8.1 Temperature Extreme temperatures may reduce the performance of alloy steel chain slings. The sling manufacturer should be consulted when the slings are to be used in temperatures of -40 oF (-40 oC) or below. Rated load reductions for Grade 80 and Grade 100 alloy chain slings used at or after exposure to temperatures above 400 oF (204 oC) or higher are given in Table 9-1.8.1-1. Shown below. EFFECT OF ELEVATED TEMPERATURE ON THE WLL OF ALLOY CHAIN Temperature Grade of Chain Grade 80 Grade 100 °F °C Reduction of Working Load Limit WHILE AT Temperature Permanent Reduction of Working Load Limit AFTER EXPOSURE to Temperature Reduction of Working Load Limit WHILE AT Temperature Permanent Reduction of Working Load Limit AFTER EXPOSURE to temperature Below 400 Below 204 None None None None 400 204 10% None 15% None 500 260 15% None 25% 5% 600 316 20% 5% 30% 15% 700 371 30% 10% 40% 20% 800 427 40% 15% 50% 25% 900 482 50% 20% 60% 30% 1000 538 60% 25% 70% 35% Over 1000 Over 538 Remove from service OSHA 1910.184 (e) Alloy Steel Chain Slings [§1910.184(e)(6)] Safe operating temperatures. Employers must permanently remove an alloy steel chain slings from service if it is heated above 1000 oF. When exposed to service temperatures in excess of 600 oF, employers must reduce the maximum working load limits permitted by the chain manufacturer in accordance with the chain or sling manufacturer’s recommendations. Sharrow Lifting Products 98 (651) 489-1341 • (800) 565-8821